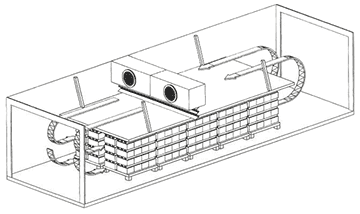

“DN 3000/2/28” set of equipment of the defrosting chambers with production capacity of 3000 kg (5600x2000x3000 mm).

We offer you a defroster of our production. Excellent proven itself in Russia. Assembled in our factory in the Kaluga region.

ADVANTAGES:

- high efficiency – fast payback

- reduction of losses – improving the quality of the product

- high degree of automation – the acceleration of the process

- Individual solutions – development possibility of production

Technical description:

Equipment set DN-3000 is designed for automatic dynamic organization of defrosting products.

| # | Name of equipment and components |

| 1.1 | Defroster airborne type DN 3000/2/28, up to 3 tons one-time loading per cycle, attached implements. With a suspended ceiling. With installation and commissioning. |

| 2.1 | Option storage, the performance with evaporator inside the defroster. Without a Refrigeration machine. |

| 2.1 | Frame for defroster, up to 600 kg load. 1 piece. Size 900х900х1800 (each product has its OWN frame) |

Package includes:

2 high-performance air heater stainless steel plants.

Ceiling frame for installation of ventilation systems.

Overlapping frames, for the organization of the wind tunnel.

Guide channels of air flow.

Trim panel for the organization of the wind tunnel.

The humidification system.

The power block.

The automation unit.

The intelligent control system MR-1000, was developed by specialists of our company, will allow you not only reliably and with high accuracy to control the process of defrosting, but will also provide real-time information about the processes occurring in defrostation chamber.

Technical characteristics of the defroster DN 3000/2/24:

Electrical installation Power 28.4 kW (heating elements – 24, fans 4,4 kW)

Estimated energy consumption per hour (when fully loaded) – about 8 kWh.

Storage after defrosting (option) – 4 kW.

Defrosting system – is dynamic, with decreasing temperature over time defrost. Maintaining a predetermined difference between the inner and outer probe. The outer surface does not overheat above 0oC at a given temperature at the end of the cycle 0oC.

Maximum volume of single loading up to 3000 kg (6 frames, 500 kg each).

The humidification system: water spray with compressed air.

Defrosting time – 6-10 hours (depends on the type of raw materials).

Dimensions – 5000x2000x3000 mm

Technical characteristics of the steam defroster (direct steam injection):

Power installation 14.4 kW (10 – heating elements, 4,4 – fan)

Steam consumption (landmark) – 48 sq m/hour

Estimated energy consumption per hour (when fully loaded) – about 4 kW per hour.

Operating principle:

In the chambers applying a patented method of airborne defrosting with a logical process control and temperature control, allowing to create optimum conditions for heat dissipation, while avoiding overheating or drying of the product surface.

The defrosting process is constantly monitored by temperature sensors in the body, on the surface of the product, as well as in the chamber. The process of defrosting is terminated automatically upon reaching a predetermined temperature in the body.

Logic control system constantly monitors the temperature of the surface of the products and the speed of the air flow, cooling the surface of the products. As a result, the surface temperature never exceeds the allowed value.

On completion of defrosting process, the chamber automatically switches to storage mode at the given temperature and acts as a warehouse until the deactivation of the program. Similarly, the chamber can be kept in the storage mode at a predetermined temperature before the start of the process, which is determined by the timer.

Meat in blocks defrostered either on racks without packaging (or tape), or directly in the boxes on the pallet, between the layers of boxes are laid out plastic grid. To complement a humidifier when working with open product necessarily, when defrosting in the boxes – it is desirable – it speeds up the process.

The meat in halves defrostered on the suspended way, strictly with humidity control system.

Poultry meat can be brought to a temperature of -3°C directly in the box, and at a predetermined temperature above -3°C is best done in lattice plastic boxes or on racks or carts of equal height.

Optimal fish defrosting comes is in a plastic layer without the cardboard, but you can also defrost open type of product. The problem of drying of the surface is resolved by enhanced performance control system of humidity.

Description of the defrosting process:

Defrosting raw material is loaded into the camera at any temperature of raw materials and chamber, however, the best result gives a uniformly frozen product. The system control parameters includes three temperature sensor and an electronic humidity sensor:

Intramuscular sensor temperature predrilled to the full depth in the largest area of raw material. The same sensor is the reference, that is exactly the temperature of the sensor is determined by the achievement of a product as given by the operator of the temperature and the time of transition from the defrosting mode to the storage mode at the set temperature.

The surface temperature sensor of the product is set at a small depth (20-30 mm) and controls the flow of heat and cold, depending on the surface condition of the product. If the surface temperature exceeds the predetermined set ∆t, on command from the sensor switches off the heat or turn on the refrigerating unit. The temperature sensor in the camera mounted on the chamber wall and controls the supply of heat and cold depending on the temperature in the chamber. During defrosting, command from this sensor turns off the heat or turn on cold when exceeding of the established operator the maximum allowable temperature in the chamber, and in the storage mode controls the refrigerating unit set predetermined temperature in the chamber defrosting.

Humidity sensor installed on the wall of the chamber so that it measures the humidity of the air after passing through defrosted product. The system controls the frequency of submission of the moisture by the humidity control system, depending on the readings of humidity and temperature in the chamber.

Request for Information

Would you like to speak to one of our advisers? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

For Businesses: Do you have questions about how RZPO can help your company? Send us an email and we’ll get in touch shortly, or phone +8(835)10001246977 between 09:00-23:00 +3 GMT Monday to Sunday — we would be delighted to speak.

Note: Your details are kept strictly confidential as per our Privacy Policy.