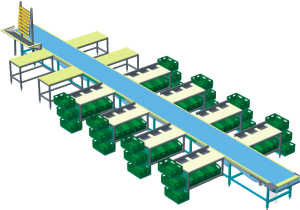

Deboning lines.

The conveyor is intended for transportation of meat raw materials in half-carcasses and quarters to workplaces of the personnel with the subsequent separation of meat from bone and sorting.

Purpose:

The billet conveyor is designed for transportation of meat raw materials in half-carcasses and quarters to workplaces of personnel with the subsequent separation of meat from bone and sorting (dozhilovki). The advantage of its use, not only in large, but also in medium-sized enterprises, is maximum optimization of production, increase in staff productivity, strict accounting of incoming raw materials on bone and varietal after cutting.

Characteristics of Deboning line

On the frame of the conveyor on the sides are fixed tables with removable countertops, which are the workplaces of personnel. Removable countertops are made of polyamide.

The conveyor belt moves along the supporting guides. The drive of the belt is carried out by means of a geared motor and a drive drum. The speed of the main conveyor belt is regulated based on the productivity of the personnel. Over the main conveyor belt is installed a tape for transportation of bones, skins and veins.

These waste products are fed into a special bunker, under which there is a plastic collection tank for waste disposal. For the convenience of sanitization, a device for cleaning the tape is provided in the supporting structure.

The number of working places and the dimensions of the conveyor are set in accordance with the wishes of the Customer.

Principle of operation:

Meat on the bone in a suspended state goes to the receiving conveyor table for rough cutting into large pieces. The carcasses of the cattle should be divided into two parts in a suspended state. Then, using a band saw on the receiving table, sawing is performed on the scapula, middle and femoral parts. With the help of the conveyor, the large parts of the carcasses are transported to the working places of the escalators to separate the meat from the bone.

In this case, large pieces of meat can be sent either for further processing, or folded into boxes (type E2) already directly for further use in production or for sale, like fresh meat. Bones, skins and other debris waste are removed using an additional conveyor that is located above the main line, and may also be subject to accounting or quality control.

Large pieces of meat, separated from the bone, on the conveyor belt come to the next jobs for sorting and dozhilovki. As a rule, beef is sorted by staff in four boxes E2, and pork at six, which are in strictly defined places near the working cutting table. As they are filled, the boxes arrive at the place of registration and registration, and empty ones arrive at their place. On the control panel, a division is made between meat for processing and large pieces for a delicacy group that can directly enter the salting and massaging area. Meat for processing comes later in the machine room for grinding on tops and cutters. Meat for storage or sale is also registered and distributed to its storage sites.

Large pieces of meat, separated from the bone, on the conveyor belt come to the next jobs for sorting and dozhilovki. As a rule, beef is sorted by staff in four boxes E2, and pork at six, which are in strictly defined places near the working cutting table. As they are filled, the boxes arrive at the place of registration and registration, and empty ones arrive at their place. On the control panel, a division is made between meat for processing and large pieces for a delicacy group that can directly enter the salting and massaging area. Meat for processing comes later in the machine room for grinding on tops and cutters. Meat for storage or sale is also registered and distributed to its storage sites.

Distribution of raw materials in conveyor lines

Automated accounting system for cutting and distribution of raw materials in conveyor lines for deboning

The system is designed for centralized operative collection of information and bringing it into a form convenient for analysis. To ensure the operation of the system to it, it is necessary to connect the balance in three technological points:

1. Weighing incoming raw materials, as well as entering the technological program by type (cattle, pork, etc.).

2. Weighing bones or, in general, waste production.

3. Weighing the meat after cutting, entering the grade and the number of the cutting table.

Automated accounting system

fully controls the productivity of the conveyor line for the production of meat in time relative to each workplace and provides the formation of reports per shift, week, month.

Monitoring system

With the additional equipment of the monitoring system with the necessary devices, it can perform the following functions:

– diagnostics of equipment operation;

– control of water and electricity consumption;

– control of personnel access to the production department.

Information levels of the system operate in parallel and independently, what ensures its “survivability” and eliminates data loss in case of possible failures. The operator can observe the technological process on a personal computer in a form convenient for analysis and perception.

Technical Characteristics of Conveyor Lines for Deboning

Length min, mm 6500

Length max, mm

6500 + 3400 x n, where n is the number of jobs

Conveyor width, mm 984

Working table dimensions, mm 1350х650

Tape crawler plastic

Band width, mm 800

Transport speed, m / min 2-12

Power, kW 1,1

Voltage, V 380

Request for Information!

Would you like to speak to one of our advisers? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

For Businesses: Do you have questions about how RZPO can help your company? Send us an email and we’ll get in touch shortly, or phone +8(835)10001246977 between 09:00-23:00 +3 GMT Monday to Sunday — we would be delighted to speak (by phone English, Russian, Bulgarian languages).

Note: Your details are kept strictly confidential as per our Privacy Policy.