Innovative system of cold drying and drying of fish and meat products Drying Stream F50.

Attention! Drying Stream F50 – obsolete, the second generation of a drying chamber.

Attention! Drying Stream F50 – obsolete, the second generation of a drying chamber.

We recommend our fourth-generation drying camera.

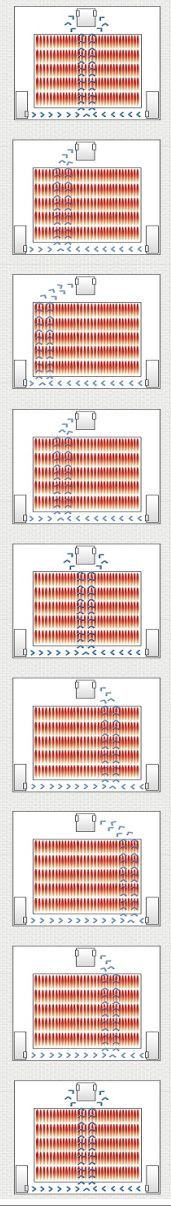

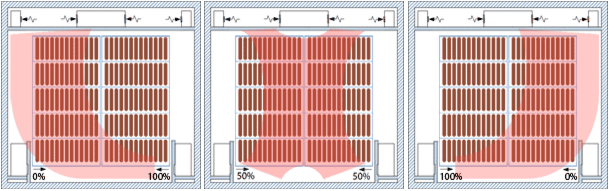

Unlike classic climatic chambers, in the Drying Stream F50 system, the nozzles opposite one another are located at the bottom of the supply air duct. With the Drying Stream F50 system, all streams became ascending and working. Air flow now does not need to overcome great resistance, reflected off the floor. Long-distance nozzles are located inside the supply air duct. And at the meeting point of the two air streams a powerful upward front is formed, moving depending on the pressure distribution system between the right and left inflow channels, which guarantees the absence of “dead” zones. Accordingly, such a system is much more preferable than traditional, for multi-row accommodation of sausage frames. When using equipment with Drying Stream F50 system, no matter how the product is placed and hung on the frame. The ascending stream to the upper exhaust channel will evenly run through all the sausage loafs, whole-muscular meat products, fish and fish fillets hung with any density. The Drying Stream F50 system is guaranteed to evenly and quickly dry the product throughout the entire volume of the camera.

The rate of cold drying of fish to GOST’s values for moisture is about small fish about 3 days, large fish – about 5 days. Drying can be intense and classical, which allows the technologist to experiment with different types of products without the danger of spoiling the most delicate product

The rate of cold drying of fish to GOST’s values for moisture is about small fish about 3 days, large fish – about 5 days. Drying can be intense and classical, which allows the technologist to experiment with different types of products without the danger of spoiling the most delicate product

Advantages of Drying Stream F50:

- Optimum energy consumption. By the finished product, we received a figure of 0.8 kW per 1 kg of finished fish. Sinets, Vobla, Chekhon, etc.

- Complete absence of “dead” zones

- Innovative economical frequency-controlled circulation system

- Powerful adjustable supply and exhaust system

- Electronic control system. Automatic control unit.

- Intuitive interface

- Effective thermodynamic drying

- Classical climate drying

- Cooling of the product

- Ultrasonic humidification

- Drying and drying of fish

- Processing of meat products

- High loading density

- Autonomy from weather conditions

- Logging of parameters

- Reliability and simplicity

- To reduce heat losses, the equipment is placed inside the chamber.

- Optionally, it can be taken out of the premises.

- Possible equipment inside the sea refrigerator container.

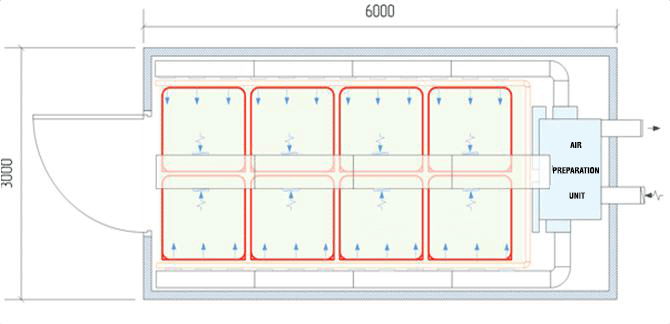

Drying Stream F50 drying chamber equipment up to 20m2

| Installed electrical power: 46kW heater: 30kW | Estimated power consumption for main modes: Drying time: 24 kW / h |

Equipment placement: built-in

Occupied area, with air conditioning unit: 20m2

Loading on the frame 250kg.

Capacity, Euro frames (1x1x2m): 8pcs

Maximum loading: 2000kg

Can be used stationary hangers with arbitrary sizes

Supply channels: 2pcs

Exhaust channel: 1 piece

Temperature control: +8 … + 40 ° С

Overall dimensions of the air preparation unit: 1400x1250x2800mm

Weight of installation: 700kg

Thermally insulated chamber from sandwich panels

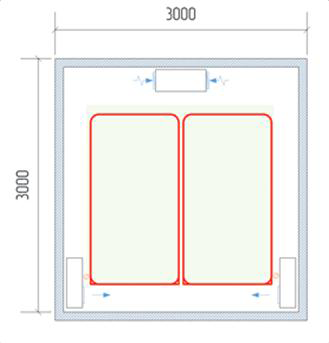

The camera is a collapsible structure of sandwich panels. It consists of floor, ceiling, wall panels, door block and fasteners. Installed on a flat, prepared surface.

The camera is a collapsible structure of sandwich panels. It consists of floor, ceiling, wall panels, door block and fasteners. Installed on a flat, prepared surface.

Execution: medium temperature

External dimensions of the camera (LxWxH): 6x3x3m

Thickness of wall panels: 60mm

Thickness of ceiling panels: 60mm

Doorway: 1200x2200mm

Door: swing-out single-leaf 1pcs

Door thickness: 80mm

Material of the surfaces of the panels: galvanized steel.

Packing dimensions: 1200x3100x1600mm

Weight: 900kg

Cooling compressor-condenser unit based on the Bitzer compressor.

This semi-hermetic piston compressor Bitzer is distinguished by the advanced design of the valve boards, the highest quality and wear resistance of crankshafts and piston-piston group, cooled by sucked-in vapors, low noise and no vibration, and a proven oil return system.

Specifications:

Specifications:

Compressor: 4EC-6Y, Oil: BSE32, 2L.

The volume of the liquid receiver: 24.8 liters. Refrigerant: R22

Cooling capacity: 17.6 kW

Boiling point: +2 ° С

Condensation temperature: 45 ° С

Voltage: 380V

Maximum operating current: 9.6A

Power consumption: 5,5 kW

Dimensions of the frame with installed equipment (LxWxH): 800x870x1600mm

Condenser air cooling HTS ATC 114.

Specifications:

Specifications:

Refrigerant: R22, Power: 24,4kW

Condensation temperature: 45 ° С

Heat exchange surface: 56m2

Internal volume: 12dm3

Air consumption: 8300m3 / h

Number of fans: 2pcs.

Diameter of fans: 450mm

Voltage: 220V

Total current: 2A

Power: 0.5 kW

Noise level at 10m: 49dBA

Dimensions (LxWxH): 1310x352x636mm

Net weight (dry): 62kg

Drying fish Camera before installation. Constructor for assembly.

Client’s placement of the drying chamber. EXAMPLE. It is desirable to place chamber in sandwich panels.

Installation of the upper exhaust duct

Installation of side upper exhaust ducts

Control panel with control panels Aditec

Control panel with Aditec control panels. View from inside the control panel.

Rear view of the exhaust and supply channels.

Ready camera inside. Bottom feed channels and top exhaust ducts.

Electric control panel with frequency converters that control the discharge fans

A fish hung in a chamber. On the 3rd day of drying

Finished uncleaned dried blue bream for 3 days.

Finished uncleaned dried blue bream for 3 days.

New economical in price and excellent in characteristics equipment for drying, ripening and ripening of raw and smoked sausages and meat products, as well as dried fish TM Drying Stream F50 ™.

At present, modern economical solutions for the production of raw and smoked products are of great interest. In the conditions of severe competition, the struggle of producers for reducing the cost of the final product, one of the main parameters is the reduction in the cost of acquiring modern equipment.

Of course, we have offered to date traditional equipment for drying raw sausages, but high prices for stainless steel, the growing wages of workers employed in European high-tech production, expensive metalworking equipment, expensive transportation services and customs duties did not allow us to offer equipment to most customers the price range they were counting on.

As a result, we could not not react to the needs of the market. It took us two years to work out all the constructive solutions, optimize each unit of equipment for drying raw and smoked sausages, to work out optimal conditions for maturing and drying. And all this is now available in Russia. As a result, we can offer drying and ripening equipment that is not inferior, and in many respects even superior to most of the offered dryers in the Russian market in terms of its technological characteristics, and at least 40% and sometimes up to 60%, cheaper than any adequate supply.

Below, we will try to answer most of the questions that have already arisen, and give the drawings and schemes of work, explain how everything works and how we managed to reduce prices so. So, we present you the Drying Stream F50 ™ system!

The main advantage of the equipment from all those present on the market, known to me, is the patented innovative air distribution system Drying Stream F50 ™, designed to optimize the movement of air inside the chamber with the product and the absence of “dead” zones. At the same time, Drying Stream F50 ™ technology is about twice as economical as traditional air distribution schemes: the capacity of the air handling unit is almost twice lower than the traditional scheme with the same speed of air flow around the product.

The thing is that in traditional dryers the power of the air handling unit is spent on overcoming by an air jet flowing from the nozzle of the supply system, the distance from the end of the nozzle to the surface of the reflection of the jet – the floor. The worker is the ascending, reflected from the floor stream. The air jet, which works to overcome the resistance of air when moving down from the nozzle, is divided into parasitic flows, about which everything is delicately hushed up and which create turbulent turbulence, drying out the nearest loaves and creating additional resistance to the main stream. And all this still works fine when the product in the camera is arranged in two rows.

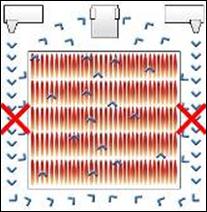

When three or more rows of placing frames with a product are used, a system of overlapping one of the channels is used to increase the air pressure at the outlet of the nozzle and, accordingly, to “purge” the central rows. And if parasitic flows during the drying of sausages of the correct geometric shape allow some penetration of air to the center of the frame, then the “wrong” products become a wall in the path of air movement. This, for example, pork hams, or rectangular sausages, or well-known fishman problems with the location of fish on the hangers. Until now, almost all manufacturers of smoking equipment, claiming that they produce fish equipment, in my opinion, look ridiculous, having hung like a sausage frame. Only instead of a sausage stick on the frame do rods for tattooing fish. As you have already understood, that the air went into the frame, the frame with the fish should have been rotated by 900 degrees!

But until now, most producers, with the obstinacy of rams, are looking for their drying problems quite elsewhere. This we say for skeptics who believe that everything was invented a long time ago. But this is not so! This is confirmed by the latest Drying Stream F50 ™ system!

The Drying Stream F50 ™ system works differently. Ducts of supply ventilation are located at the bottom of the chamber. The nozzles located opposite each other are located at the bottom of the supply air duct. Since the air flow does not need to overcome great resistance, the nozzles, which are sufficiently long-range for solving their problems, are located inside the supply air duct. With the Drying Stream F50 ™ system, all streams became ascending and working. And at the meeting point of the two air streams a powerful upward front is formed, moving depending on the pressure distribution system between the right and left inflow channels. That guarantees the absence of “dead” zones. Accordingly, such a system is much more preferable than traditional, for multi-row accommodation of sausage frames. When using equipment with the Drying Stream F50 ™ system, no matter how the product is placed and hung on the frame. The upward flow to the upper exhaust channel will evenly run through all the products, preventing the formation of mold from “stagnant” zones and it is guaranteed to evenly dry the product.

When using the Drying Stream F50 ™ system, the air supply ducts are protected by restrictors that protect the air ducts from contact with the frames and allow the sausage frame to be clearly positioned in the working air flow area.

Request for Information!

Would you like to speak to one of our advisers? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

For Businesses: Do you have questions about how RZPO can help your company? Send us an email and we’ll get in touch shortly, or phone +8(835)10001246977 between 09:00-23:00 +3 GMT Monday to Sunday — we would be delighted to speak (by phone English, Russian, Bulgarian languages).

Note: Your details are kept strictly confidential as per our Privacy Policy.