DEFROSTATION, FROST, FREEZE PROCESS

New technologies – the advantages of multifunctionality.

New technologies – the advantages of multifunctionality.

- high profitability – quick payback

- reduction of losses – improvement of quality of meat

- a high degree of automation – speeding up the process

- individual solutions – the possibility of production development

Defrosting chambers

High economy – a defrosting process with logical control reduces losses.

Equipped with logic control, defrosting and freezing chambers, using air currents, heat and refrigeration equipment, allow the frozen meat, fish and other food products to be thawed and frozen in an optimal and highly economical mode. Only this method allows to avoid losses in the weight of the defrosted product.

High quality – the new technology ensures a quick and even process

Ease of operation – the possibility of an end-to-end process.

Logical control system constantly monitors the surface temperature of products and the speed of air flows that cool the surface of products. This allows rapid defrosting with low heat consumption. Depending on the product and the dimensions of the chamber, the defrosting time from -250C to -20C varies from 6 to 10 hours.

The camera can be used as a cold store.

Prior to and after the end of the defrosting process or the freezing of the product in the chamber, a stable temperature is maintained and acts as a refrigeration or freezing warehouse in accordance with the specified program. Due to this, the camera can be released at any convenient pace for production, while the products will maintain the necessary temperature.

Individual solutions – the possibility of using existing premises

Products can also be delivered in components, with the unit of units with overlapping and control system supplied without the actual camera. Thus, you can use available space. Installation of equipment and commissioning are simple and quick.

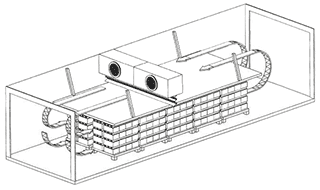

The process of defrosting and freezing is provided by a compact unit of units using the possibilities of airflow, heat and refrigeration. The equipment is designed in such a way that a block of aggregates and an adjustable overlap form a wind tunnel. Both the engineering solution and the idea of a wind tunnel are protected by patents.

Hygienic and reliable operation

The container is made of an ST-sandwich element developed and approved for use in the food industry. Cleaning the container and individual items is very simple. Thus, the production process becomes very hygienic.

Controlling the temperature on the surface of the product and in the body, as well as the internal temperature of the chamber, it is possible to carry out the processes of defrosting and freezing without loss of moisture and weight.

Technical data of Defrosting chambers

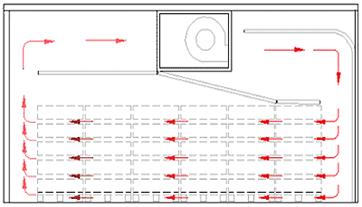

Operating principle

The process of defrosting is constantly monitored by temperature sensors in the body, on the surface of the product, and also in the chamber. The process of defrosting is completed automatically, after reaching the set temperature in the body.

Logical control system constantly monitors the surface temperature of products and the speed of air flows that cool the surface of products. As a result, the surface temperature never exceeds the permissible value.

At the end of the defrosting process, the camera automatically goes into the storage mode at the specified temperature and acts as a warehouse until the program is disconnected. Similarly, the camera can be kept in the storage mode at the set temperature until the start of the process, which is determined by the timer.

The camera is also supplied with underfeed equipment, which allows you to prepare products for thin slices. This can optimize the use of the camera and shorten the payback period.

The process of defrosting is constantly monitored by temperature sensors in the body, on the surface of the product, and also in the chamber. The process of defrosting is completed automatically, after reaching the set temperature in the body.

Logical control system constantly monitors the surface temperature of products and the speed of air flows that cool the surface of products. As a result, the surface temperature never exceeds the permissible value.

At the end of the defrosting process, the camera automatically goes into the storage mode at the specified temperature and acts as a warehouse until the program is disconnected. Similarly, the camera can be kept in the storage mode at the set temperature until the start of the process, which is determined by the timer.

The camera is also supplied with underfeed equipment, which allows you to prepare products for thin slices. This can optimize the use of the camera and shorten the payback period.

Design of chambers

The defrosting chamber is made of an ST-sandwich element developed and approved for use in the food industry. The ST-sandwich element is a load-bearing panel of a plastic-coated water-resistant polystyrene insulator.

Own production

The company produces chambers, containers and cabinets of various sizes for the defrosting of packaged and unpackaged meat, poultry and fish with a productivity of 0.3 to 15 tons. It is also possible to supply a set of equipment, logic and software for installation in your premises. It should be remembered that the design of aggregates for cameras of non-standard dimensions increases the cost of equipment. Dimensions and cost of standard cameras are reflected in the price list.

The cameras use the patented method of airborne droplet defrosting with logical control of the process and temperature control, which allows creating optimal conditions for heat removal, while avoiding overheating or drying of the product surface.

Scheme of defrosting

Meat in blocks is defrosted either on racks without packaging (or in film), or directly in boxes on a pallet, plastic lattices are laid between the layers of boxes. To supplement the air humidifier when working with an open product is mandatory, with defrosting in boxes – preferably – this speeds up the process.

Meat in half-corpses is defrosted on a suspension track, strictly with a humidity control system.

Poultry meat can be brought to a temperature of -3 ° C directly in the box, and for a given temperature above -3 ° C it is better to do this in plastic crates or on racks or trolleys of equal height.

Optimal defrostation of fish occurs in a plastic film without cardboard, but it is also possible to defrost the open product. The problem of drying the surface is solved by means of a humidity control system with increased productivity.

Chambers from a strong and hygienic ST sandwich retain their strength characteristics for decades (the unit of overlapping units is suspended directly to the ceiling of the chamber without special fittings) and the hygiene level of the entire room due to the absence of condensation points inside the material. Kometos does not guarantee the observance of the declared defrosting parameters in the chambers of other manufacturers. An additional door to the opposite end of the camera allows for an end-to-end process. Since the end of the defrosting process in the scheme we are using automatically takes the camera to the storage mode at a given defrosting temperature, the uniformity of the production load is ensured by maintaining the preset temperature in the chamber.

Description of the defrosting process:

The defrosted raw material is loaded into the chamber at any temperature of the raw material and the chamber, however, the uniformly frozen product gives the optimum result. The monitoring system includes three temperature sensors and an electronic humidity sensor:

The sensor of intramuscular temperature is drilled into full depth into the largest part of the raw material. The same sensor is preset, that is, it is the temperature from this sensor that determines the product’s achievement of the temperature specified by the operator and the moment of transition from the defrosting mode to the storage mode at a given temperature.

The surface temperature sensor is installed at a shallow depth (20-30 mm) and controls the supply of heat and cold, depending on the state of the product surface. If the surface temperature exceeds the set temperature by the set Δt, the heat supply is turned off when the command is made from this sensor or the refrigeration unit is turned on.

The temperature sensor in the chamber is installed on the wall of the chamber and controls the supply of heat and cold, depending on the temperature in the chamber. During defrosting, the command from this sensor switches off the heat or turns on the cold when the maximum permissible temperature in the chamber is set by the operator, and in the storage mode the refrigerating unit controls the preset defrosting temperature in the chamber.

The humidity sensor is mounted on the wall of the chamber so that it measures the humidity of the air after passing through the defrosted product. The system controls the frequency of moisture supply by the humidity control system, depending on the humidity and temperature in the chamber.

The unit of stainless steel units (under the ceiling above the ceiling or in the floor version) includes a system of sensor-controlled temperatures and humidity, as well as the logic of fans, heaters, a refrigeration unit and a humidity control system.

After installing the sensors in the product, the operator enters the main parameters on the control panel display: the set temperature, the maximum permissible temperature in the chamber, humidity (up to 99%) and Δt (that is, the maximum permissible temperature rise of the surface of the set temperature) can also be adjusted. This parameter affects both the rate of defrosting and the level of losses. Defined in the commercial proposal, the defrosting and losses are determined for block scandinavian raw materials at Δt = + 3.5 ° C and the dimensions of the blocks are 600 * 400 * 150 mm. This means that at a specified temperature of + 1 ° C, the surface temperature will not exceed during the defrosting process of the indicator + 4.5 ° C. It is under these conditions that the losses will not be more than 1.8%. A decrease in Δt will lead to a reduction in losses and an increase in the duration of the process, an increase in this indicator will increase losses, but will speed up the process.

After the start of the defrosting program by the START button, the process proceeds in such a way that the humidified air flows at a speed of 6-12 m / s, heated by the TENs to full capacity, begin to remove the cold from the defrosted product as quickly as possible. After reaching the maximum permissible temperature in the chamber, the heating begins to periodically switch off and take away the cold of the internal mass of the product. Similarly, by turning off the heaters or even turning on the cold, the equipment responds to reaching the temperature equal to the specified + Δt, preventing the surface of the product from overheating and starting to lose moisture.

After the temperature in the body reaches the set temperature (more precisely by 0.5 ° C less than the set temperature), the process of defrosting with airflows stops, while the STOP button does not turn off the defroster with the STOP button, because the camera will automatically enter the mode of maintaining the set temperature. At the same time, it is possible to begin to unload the defrosted raw materials, while maintaining the confidence that the temperature of the raw material remaining in the chamber will not increase, but will further equalize.

Dimensions of the defroster with one standard unit of units:

1. Defrosting of block raw materials (meat, fish, poultry) in a box or without, on pallets with spacers or on racks:

– internal width not exceeding 2,600 mm;

– length MT-S (up to 10 tons) no more than 10.000 mm (optimally 6-8 meters)

– length MT-XL (up to 14 tons) no more than 12.000 mm (optimally 9-11 meters)

2. Defrosting half-carcasses and quarters on the suspension track (from 7 to 15 tons):

– internal width of 2.600 or 5.100 mm;

– length from 6.000 to 15.000 mm

The general requirements for standard cameras are:

– the presence of three-phase power supply 400V / 80A -125A. Power cable copper 5 * 25-35 mm2.

– availability of networked water supply and compressed air (for products requiring moisture control, for example, unpackaged meat, fish), the volume is small, you can install a conventional compressor. Minimum water pressure 3 atm., Flow rate from 12 to 40 l / h. Compressed air with a pressure of at least 4 atm., Flow rate 50 l / h (with the defrosting of the fish, the water consumption is 2 times greater).

Dimensions and parameters of systems for non-standard solutions are calculated in each case individually.

The company performs supervision, equipment adjustment, as well as training in operation and maintenance skills. Operation is simple, maintenance is minimal and does not require special training.

№ | Name of equipment and components |

1.1 | Defroster air-drip type DN 3000/2/28, up to 3 tons of one-time loading per cycle, attachments. With a suspended ceiling. With installation and commissioning. |

2.1 | Option storage, version with evaporator inside the defroster. Without a refrigeration machine. |

2.1 | Frame for defroster, up to 600 kg of load. 1 piece. Size 900x900x1800 (for each product its own frame) |

Request for Information!

Would you like to speak to one of our advisers? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

For Businesses: Do you have questions about how RZPO can help your company? Send us an email and we’ll get in touch shortly, or phone +8(835)10001246977 between 09:00-23:00 +3 GMT Monday to Sunday — we would be delighted to speak (by phone English, Russian, Bulgarian languages).

Note: Your details are kept strictly confidential as per our Privacy Policy.