The basic principles of the defrosting process

The basic principles of the defrosting process are the underlying actions of the JUGEMA programmable defroster.

The goal of defrosting frozen food products is to heat them to give properties close to those of unfrozen foods. The most common method of defrosting is the heat treatment of frozen foods in the air. With all methods of heat treatment of frozen food in the air, an increased air humidity is created within 85 … 95% (conditions of the steam-air medium).

During defrosting, food products are heated to a temperature at which their further processing is possible.

Ice cream of meat and fish raw materials is defrosted to + 1C, if after heat treatment it goes to the cutting and cutting for further use in sausage and canning. Since unfrozen meat and fish raw materials are recycled for immediate use, then during unfreezing, a high air temperature of 20 … 22C and an elevated relative humidity of 85 … 95% are used. At the same time, the air velocity does not exceed 2.5 m / s.

Ice cream meat and fish raw materials in blocks warm up to – 5 … – 6C, if it immediately goes to machine processing for sausage, canning and other types of production.

Ice-cream meat and fish raw materials in blocks are thawed to 00C, if it is intended for the production of delicacies (baked pork, carbonat, tongues, fish fillets, etc.). In order to preserve the quality indicators and reduce the weight loss, the delicatessen raw material is thawed at a reduced air temperature of 10: 12C (for fish blocks, the temperature of the air in some cases is increased to 25C) and 85: 95% relative humidity. The circulating air velocity is basically 1 … 2m / s. When the fish blocks are defrosted, the air speed reaches 5 m / s.

Defrosting meat and fish raw materials

The low temperature of air during defrosting of deli meats and all kinds of fish raw materials is explained by the need:

1) to exclude an increase in the temperature of the surface layer in order to reduce shrinkage and maintain quality indicators of raw materials;

2) avoid condensation of water vapor from the air on the surface of heated blocks during the manufacture of meat and fish products.

In the departments for the production of meat and fish products, as well as in raw materials for sausage and canning, the temperature is maintained at 12C and the relative humidity is 70%. The temperature of the dew point of air with such parameters is 6.5C. After heating, the temperature on the surface of the blocks is 9..10 ° C, tf, tp> tp. Consequently, the condensation conditions of water vapor are excluded. But with the defrosting of blocks, in most cases condensation of water vapor can not be avoided during the entire process. With average parameters of circulating air of 10: 12C and humidity of 85 … 95%, the temperature of its dew point is 7.5 … 9C. In this case, the temperature of the surface of the thawed raw material changes from -10 … -18 C to 9 … 10C. Consequently, the whole process of heat treatment of blocks is accompanied by the condensation of water vapor from the air. And only at the last stage of defrosting, when tp> tp, moisture will evaporate from the surface of the blocks. Therefore, defrosting blocks of scrap, lumpy meats and other raw materials that do not have a protective layer are performed in the packaging film, which allows to preserve the sanitary and hygienic state of the raw materials to a greater extent.

Frozen butter blocks for the production of a packed product packed in bundles of a given mass are thawed under the same temperature conditions as blocks of delicacy meat and fish raw materials.

During the defrosting

During the defrosting of meat and fish raw materials at elevated air temperature, the heating of products takes place in two stages.

The first stage is characterized by the conditions of condensation of water lasers from the air (since the temperature of the surface of the ice-cream raw material is less than the temperature of the dew point of the air), with the condensate first appearing in the form of frost on the surface of the products until the surface temperature becomes above 0C, and then in the form Water, along with the condensate from the surface, some of the nutrients are lost, and the initial quality indices of meat are deteriorating to some extent. Therefore, the duration of the first stage tend to be reduced as much as possible.

In the second stage, when the temperature of the product surface becomes higher than the dew point of the air, the periods of evaporation and condensation of moisture on the surface alternate. At an air temperature of 20C and an average relative humidity of 90%, the duration of the first stage is approximately one-fourth of the total duration of the process if the air speed is 1.5: 2 m / s. At this time, the heating and humidifying system carries out a constant supply of heat and moisture. The second stage of heat treatment of ice cream raw material is characterized by the periodic inclusion of the heating and humidifying system while maintaining the set air temperature within + -1C.

The average surface temperature of the product remains almost constant and less than the average air temperature by about 2C. The change in surface temperature is no more than + -0.3C with a change in air temperature within + -1C.

Relative air humidity is maintained within + -5% and varies from 85 to 95%. With a different combination of regulated air parameters (temperature and relative humidity), periods of evaporation of moisture and condensation of it on the surface of the product alternate.

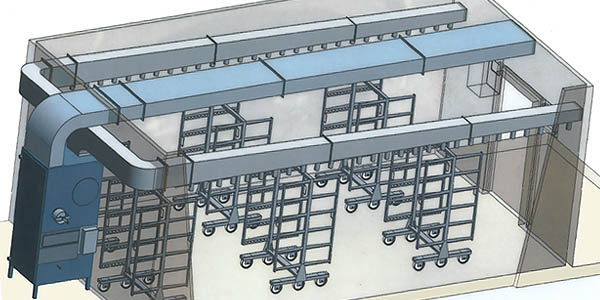

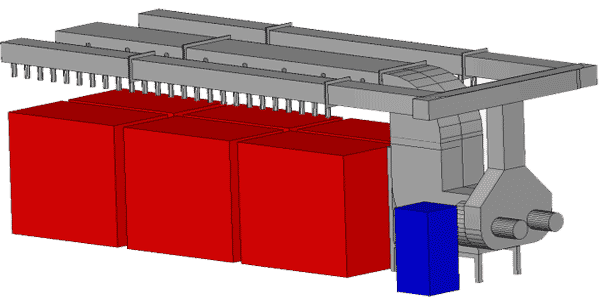

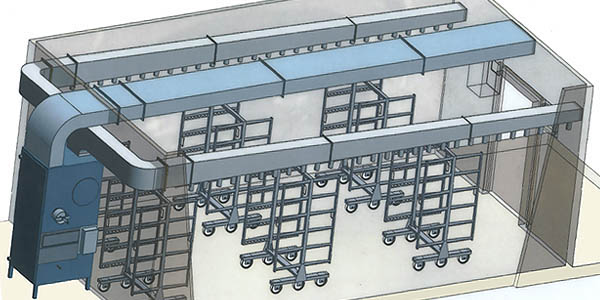

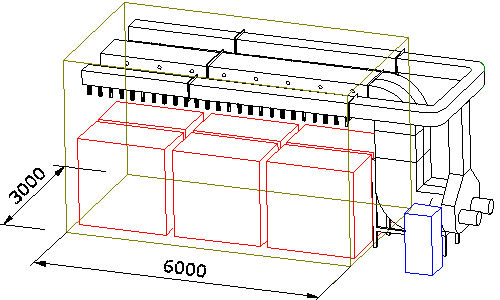

Typical set of equipment for defrosting meat and fish blocks JUGEMA DE 4000.

Capacity conditional about 10t / day. 180 blocks one-time download.

The approximate time of the defrosting process is 6 hours.

Defroster Specifications

- The heating system is electrical,

- Humidification system: double: water spray + steam generator (10kg / h),

- Dimensions of the room for defrosting 6000mm (length) x 3000mm (width) x 3500mm (height),

- Rack dimensions: 900 mm (width) x 1620 mm (length) x 1600 mm (height) – 6 levels,

- Ventilation: variable flow direction in time, possibility of smooth adjustment.

- Installed power:

- – The fan is 4.8 kW,

- – heating – 54.0 kW,

- – steam generator – 7,5 kW,

- – drive for changing the flow direction – 0,75 kW

- Full power: 67,0 kW

- Control: microprocessor – ADITEC MIC 2410 (russified).

- Measurement and temperature control inside the defroster,

- Block temperature measurement,

- Measurement of relative humidity

Delivery set of defroster

A door with a window,

- Suction pipe,

- Air injection pipes,

- The air preparation unit,

- The steam generator,

- Control panel with microprocessor.

Additional equipment: Refrigeration equipment for storage mode.

The JUGEMA defroster is designed for existing production facilities.

| Product temperature, C | Beef, bird | Mutton | Pork | Flesh by-products | Lean fish | Non Lean fish | Fish fillets |

|---|---|---|---|---|---|---|---|

| -20 | 0,0 | 0,0 | 0,0 | 0,0 | 0,0 | 0,0 | 0,0 |

| -18 | 4,6 | 4,6 | 4,6 | 5,0 | 5,0 | 5,0 | 5,4 |

| -15 | 13,0 | 12,6 | 12,2 | 13,8 | 14,3 | 14,3 | 14,7 |

| -12 | 22,2 | 21,8 | 21,4 | 24,4 | 24,8 | 24,4 | 25,6 |

| -10 | 30,2 | 29,8 | 28,9 | 33,2 | 33,6 | 32,7 | 34,8 |

| -8 | 39,4 | 38,5 | 34,8 | 43,1 | 43,5 | 42,3 | 45,7 |

| -5 | 57,3 | 55,6 | 54,4 | 62,8 | 64,0 | 62,5 | 67,0 |

| -3 | 75,3 | 74,0 | 73,3 | 87,9 | 88,4 | 85,5 | 93,9 |

| -2 | 98,8 | 95,8 | 91,6 | 109,6 | 81,6 | 106,2 | 87,7 |

| -1 | 185,5 | 179,5 | 170,0 | 204,0 | 212,2 | 199,8 | 225,0 |

| 0 | 232,2 | 224,0 | 28,8 | 261,0 | 265,8 | 249,0 | 282,0 |

| 1 | 235,5 | 227,0 | 214,7 | 264,5 | 269,5 | 252,0 | 285,8 |

| 2 | 238,2 | 230,0 | 217,8 | 268,3 | 272,9 | 256,0 | 289,1 |

| 4 | 245,5 | 236,3 | 224,0 | 274,3 | 280,0 | 262,6 | 296,7 |

| 8 | 248,2 | 249,0 | 235,8 | 289,2 | 293,9 | 277,0 | 38,3 |

| 10 | 264,5 | 255,3 | 241,7 | 290,0 | 301,0 | 283,0 | 318,4 |

| 12 | 270,8 | 261,4 | 248,2 | 302,2 | 308,0 | 290,0 | 326,0 |

| 15 | 280,4 | 271,2 | 256,8 | 312,8 | 314,4 | 300,4 | 336,9 |

| 20 | 296,8 | 286,7 | 272,5 | 330,6 | 336,0 | 317,4 | 355,3 |

| 25 | 312,0 | 301,8 | 287,7 | 348,0 | 353,6 | 334,4 | 373,3 |

Request for Information!

Would you like to speak to one of our advisers? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

For Businesses: Do you have questions about how RZPO can help your company? Send us an email and we’ll get in touch shortly, or phone +8(835)10001246977 between 09:00-23:00 +3 GMT Monday to Sunday — we would be delighted to speak (by phone English, Russian, Bulgarian languages).

Note: Your details are kept strictly confidential as per our Privacy Policy.