Smoking and ripening chamber of raw or smoked sausages

Dear colleagues!

We offer you our climate chambers SCRC (smoking camera and ripening chamber of raw or smoked sausages). Also our company produces climate control systems KDSC. In this proposal, we offer you a 12 euroframes SCRC camera for ripening and smoking of sausages and meat products with a capacity of up to 2.4 tons of products in raw materials (based on 200 kg of products per 1 frame). Output of finished products (landmark) 1800 kg per cycle.

| No. | Name of equipment |

| 1.1 | Climate chambers SCRC (smoking and ripening chamber of raw or smoked sausages) with a capacity of 2×6 = 12 euroframes. Complete with a smoke generator DGSCH-100A |

Note: The cost of the equipment does not include sandwich panels, doors and refrigerators. They are selected on the site according to the parameters issued by the RZPO.

The use of our equipment gives you a guaranteed high quality, constantly controlled and adjustable parameters of the air inside the chamber: temperature, humidity and speed and direction of air flow. And it will allow you to take the leading place in your region for the products you produce.

The warranty is 18 months from the date the equipment is put into operation, but no more than 19 months from the date of shipment from the warehouse in Podolsk.

1.1 Climate chambers SCRC (smoking and ripening chamber of raw or smoked sausages) and KDSC (chamber for ripening raw and smoked sausages).

Designed for ripening, afterripening, cold smoking and storage of smoked and boiled-smoked sausages. Provide the necessary optimal climatic conditions and speed of air exchange inside the climate chamber. Provide: cold smoking, drying, heating, moisturizing, cooling.

Packaging and version

Thanks to the application of advanced German technologies in the design and manufacture of climate plants SCRC and KDSC, the process of ripening and drying of the smoked and boiled-smoked products become absolutely manageable. Allow to fully control and automatically adjust:

- Humidity and temperature in the chamber

- Air flow speed

- Direction of movement and air exchange over the entire capacity of the climatic chamber

All this allows to receive exceptionally high and stable quality of smoked and boiled sausages.

Thanks to the use of the most modern automatic control panels from Siemens (Austria) and Mikster (Poland) in the climate chamber control, it became possible to combine, during the ripening of raw and smoked sausages, 2 logical schemes for controlling the ripening process of meat: southern (Italian, similar to Travalini) and northern (German, Companies: Vemag, Ness and others) a maturation scheme.

Installations are made entirely of stainless steel imported production using the assembly of leading industrial enterprises in Germany (electronics, driving gear, etc.). Thermal insulation enclosing structures are made of standard or stainless steel sandwich panels. The KDSC of the RZPO production is installed outside or inside a prepared and thermally insulated premises. Under the individual order, the climate unit is equipped with a cold smoking system. A stainless steel thermal insulation door can be included in the delivery set. The minimum recommended capacity of one camera is 4 euroframes.

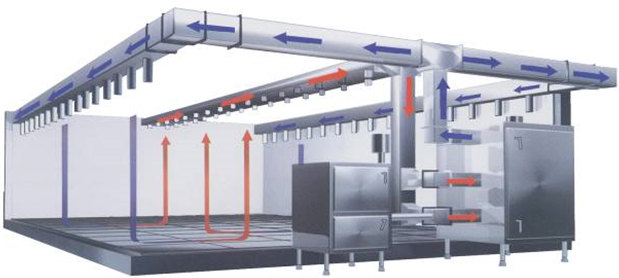

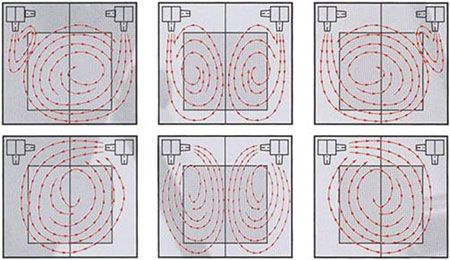

The circulation of the air flows

To optimize the process of drying output of the product in air-conditioning systems, variable air circulation directions are used. The applied method gives the advantage of maximum mixing of the atmosphere in the chamber and eliminates the so-called “dead zones” throughout the volume

Scheme of the directions of air and heat exchange:

Sanitation

All parts of the KDSC, including air ducts, are available for sanitary treatment with detergent solutions, which significantly reduces the risk of microbiological insemination of products.

SPECIFICATIONS

- Adjustment ranges: – temperatures from 12 to 30 ºС

– humidity from 50 to 98%

– speed of air flow from 0,1 to 2 m/s

- the product is placed and transported on movable universal frames

- the number of loadable frames with the product (1000х1000х1970 mm) – 10 pcs.

- active exhaust ventilation system with adjustable modes

- automatic control and regulation system based on the INDU IMAX 500 controller with a 5.7 “touch screen

- the presence of temperature sensors in the chamber, the temperature in the product and the relative humidity of the working medium

- automatic regulation and maintenance of relative humidity and temperature in the chamber

- pneumatic control system for air dampers (Camozzi – Italy)

- Frequency control of the rotational speed of the ventilation fan motor

- frequency control by the speed of rotation of the exhaust fan motor

- installed power of electric motors of all groups, when using frequency regulation of the speed of rotation of circulating engines up to 13 kW.

- installed capacity of electric heating elements for heating the camera – 24 kW.

- built-in stainless steel evaporator with a capacity of up to 24 kW in the cold (on all types of chambers)

Overall dimensions and power characteristics of SCRC. All SCRC are designed for 2 rows of frames.

| Type | Number of frames, pcs. | Internal camera dimensions | Power in the cold of the camera, kW | Power of the camera, kW | ||

| Width, m | Depth, m | Height, m | ||||

| SCRC -12 | 12 | 3,3 | 6,5 | 3,0 | 24 | 37,3 |

The control panel iMAX 500

- Provides comprehensive, automatic control and regulation of the heat chamber on individual technology programs.

- The parameters are constantly shown on the display:

– the temperature inside the product

– relative air humidity in the chamber

– working out time of technological steps (elapsed time)

- The control panel is connected to a personal computer via the MRS program to control all the processes of the camera and the ability to print charts.

Cold smoking system

The process of intensive cold smoking is provided by equipping SCRC climatic installations with a refrigeration unit and a smoke generator with automatic chipboard DGSCH-100A. The peculiarity of this smoke generator is that we control the temperature of chip smoldering. At the same time, we can maintain the required temperature of decay EXACTLY for that type of wood. This gives control over: combustion, obtaining aromatic and coloring substances. In our DGSCH equipment there are 3 fire extinguishing systems: air supply restriction, mixing of sawdust and water quenching. Before extinguishing with water does not come.

The stainless steel evaporator for the refrigerating chamber is made on special order. Evaporator is resistant to active cleaning solutions.

DGSCH-100A is equipped with a fire extinguishing system, which avoids the involuntary ignition of sawdust. Below is a description of the smoke generator. Can be supplied as a separate unit.

The automatic chip generator DGSCH-100A (pictured right).

- microcontroller, Siemens LCD operator panel (Germany)

- smoke generator manufactured from stainless steel;

- packaging with electro-pneumatic actuator system of the “CAMOZZI” company (Italy);

- simplicity and convenience of service;

- The recommended fraction of wood chips is 5-15 mm;

- filling of the chamber with smoke to a working concentration for 3-4 minutes;

- automatic feeding of chips from the hopper into the smoldering zone;

- automatic ignition of chips;

- automatic smoke temperature control;

- automatic control of chip smoldering temperature;

- automatic attenuation of chip smoldering;

- automatic emergency extinguishing of chips when the smoke temperature exceeds the set value;

- Smoke density adjustment

- Removable grate bars for easy cleaning, cleaning and maintenance, as well as for the use of chips of different fractions

The photo shows the chips after smoldering in the grate of the smoke generator. EFFICIENCY is 100%.

Request for Information!

Would you like to speak to one of our advisers? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

For Businesses: Do you have questions about how RZPO can help your company? Send us an email and we’ll get in touch shortly, or phone +8(835)10001246977 between 09:00-23:00 +3 GMT Monday to Sunday — we would be delighted to speak (by phone English, Russian, Bulgarian languages).

Note: Your details are kept strictly confidential as per our Privacy Policy.