Climatic installations for meat.

Climatic installations KLIMATRONIK is the equipment intended for the production of raw and smoked meat products of the highest quality.

Based on many years of experience in the manufacture of equipment for the production of raw smoked meat products, RZPO offers the following types of climatic installations, designed exactly for your needs

Climatic plants for maturation and smoking KLIMATRONIK type KLK (from 6 to 48 frames)

the products go through the stages of temperature equalization, the most intensive moisture removal, color formation, the formation of a microbiologically stable acidic medium (pH) and the preservation of the moisture permeability of the shell for the optimal course of the drying process;

the products go through the stages of temperature equalization, the most intensive moisture removal, color formation, the formation of a microbiologically stable acidic medium (pH) and the preservation of the moisture permeability of the shell for the optimal course of the drying process;- in the climate chamber, uniform scanning of air currents in the horizontal and vertical direction is ensured with precise regulation of the flow velocity;

- operating modes: – temperature from 12 to 30 ° C,

- humidity from 70 to 98%.

Climatic complexes KLIMATRONIK manufactured by RZPO are a system of climate chambers made of sandwich panels (stainless steel or polyester varnish). Based on your wishes, the climate units can also be integrated into existing premises and adapted to the specific conditions of your enterprise. The quantitative composition and type of equipment is regulated by the required productivity of the complex, as well as the desired technology for the production of raw-smoking products. Specialists of the company “RZPO” will provide full support of your project from design to the moment of commissioning the equipment and obtaining finished products. The best technical and technological solutions are the result of our work to ensure your success in the production of raw products.

Climatic complexes produced by the company “RZPO” characterize first and foremost the highest quality and attractive appetizing appearance of the smoked products made with the help of climatic plants KLIMATRONIK. This is the best recommendation in your choice of equipment.

The intelligent control system MP-1000

The intelligent control system MP-1000, developed by the specialists of the company “RZPO”, will allow you to not only reliably and with high accuracy control the processes of maturation, drying, storage, but also provide real-time information about the main processes occurring in the climatic chamber at intervals up to 30 seconds. All information is received on the personal computer of the technologist in the format of the protocol of the technological process, which allows for detailed analysis and work on errors.

With the intelligent control system MP1000, you can not only enter up to 40 desired technological programs with 30 steps each, but also get information about the following important parameters:

- Display of technological parameters on the screen

- Entering a technological program and monitoring its execution

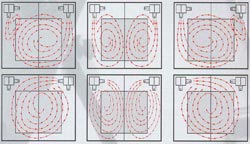

- Distribution of air flows by volume of the climatic chamber

- Report on the loss of weight of the product for the past time and predicting it for the future

- Recommended parameter setting option

The unique recommended option of the MP-1000 control system allows the technologist to avoid mistakes when setting the technological program in the ratio of temperature and humidity, which is signaled by a warning signal. The system blocks the setting of erroneous parameters and suggests choosing the right ones, which makes it possible to avoid condensation on the product and, as a consequence, undesirable mold.

Intelligent control system MP-1000 is constantly self-diagnosed, which excludes its malfunction due to possible malfunctions. This significantly increases the reliability potential of both the individual climate unit KLIMATRONIK and the entire complex as a whole.

As an energy-saving option in the KLIMATRONIK installation, steam heating of air can be installed.

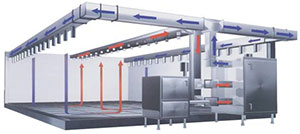

One of the priority parameters in obtaining high-quality raw smoked products is the direction and speed of the air flow. In climatic installations KLIMATRONIK specialists of the company “RZPO” realized the method of scanning by airflow of the entire volume of the climatic chamber both horizontally and vertically, which completely eliminates the formation of “stagnant zones” in the chamber and, as a result, the formation of mold on the product . With the help of precise control of the speed of the blowing fan, the optimum airflow speed is required for this process.

Distribution of air flows

Horizontal and vertical scanning

Section of climatic chamber

Due to the absolute controllability of the air flow in the climatic chambers KLIMATRONIK, the drying process proceeds in the best way, without the formation of the dried edge of the shell (hardening), and the finished products have an attractive appearance for the customers.

Many years of experience in the operation of KLIMATRONIK climatic plants in Ukraine and in the countries of the Near and Far Abroad proved their high reliability, efficiency and functionality.

Technical specifications

Regulating ranges:

- temperature from +12 to +30 ºС

- humidity from 70 to 98%

- speed of air flow from 0,1 to 0,8 m / s

Climatic installations Klimatronik for ripening and smoking of smoked sausages, without refrigerating machines

| installation type KLIMATRONIK | Number of frames | number of rows | internal camera dimensions | area of sandwich panels, m² | capacity of refrigerating machine, kW | Installing power with smoke generator, kW | ||

| ширина м | глубина м | высота м | ||||||

| KLK-6 | 6 | 2 | 3,3 | 4,6 | 3,0 | 69 | 10,2 | 21,4 |

| KLK-8 | 8 | 2 | 3,3 | 5,8 | 3,0 | 81 | 13,6 | 21,4 |

| KLK-10 | 10 | 2 | 3,3 | 7,0 | 3,0 | 92 | 17 | 29,4 |

| KLK-12 | 12 | 2 | 3,3 | 8,0 | 3,0 | 103 | 20,4 | 35,2 |

| KLK-14 | 14 | 2 | 3,3 | 9,2 | 3,0 | 114 | 23,8 | 40,4 |

| KLK-16 | 16 | 2 | 3,3 | 11,0 | 3,0 | 134 | 27,2 | 49,2 |

| KLK-18 | 18 | 2 | 3,3 | 12,7 | 3,0 | 149 | 30,6 | 51,5 |

| KLK-20 | 20 | 2 | 3,3 | 11,5 | 3,0 | 137 | 34 | 60,7 |

| KLK-22 | 22 | 2 | 3,3 | 12,6 | 3,0 | 148 | 37,4 | 66,0 |

| KLK-24 | 24 | 2 | 3,3 | 13,8 | 3,0 | 160 | 40,8 | 71,5 |

Climatic installations Klimatronik for ripening, drying and storage of raw smoked sausages, without refrigerating machines

| installation type KLIMATRONIK | Number of frames | number of rows | internal camera dimensions | area of sandwich panels, m² | capacity of refrigerating machine, kW | Installing power with smoke generator, kW | ||

| ширина м | глубина м | высота м | ||||||

| KLSD-12 | 12 | 2 | 3,3 | 8,0 | 3,0 | 103 | 8,2 | 15,3 |

3 | 4,5 | 5,6 | 3,0 | 95 | ||||

| KLSD-16 | 16 | 2 | 3,3 | 11,0 | 3,0 | 134 | 11 | 20,9 |

4 | 6,2 | 5,6 | 3,0 | 116 | ||||

| KLSD-18 | 18 | 2 | 3,3 | 12,7 | 3,0 | 149 | 12,3 | 20,9 |

3 | 4,5 | 8,0 | 3,0 | 120 | ||||

| KLSD-20 | 20 | 2 | 3,3 | 13,8 | 3,0 | 161 | 13,6 | 26,0 |

4 | 6,2 | 6,9 | 3,0 | 131 | ||||

| KLSD-24 | 24 | 2 | 3,3 | 16,0 | 3,0 | 184 | 16,3 | 26,0 |

3 | 4,5 | 11,0 | 3,0 | 155 | ||||

4 | 6,2 | 8,0 | 3,0 | 146 | ||||

| KLSD-28 | 28 | 2 | 3,3 | 18,3 | 3,0 | 205 | 19 | 34,0 |

4 | 6,2 | 9,2 | 3,0 | 159 | 34,0 | |||

| KLSD-30 | 30 | 3 | 4,5 | 13,8 | 3,0 | 184 | 20,4 | 34,0 |

| KLSD-32 | 32 | 4 | 6,2 | 11,0 | 3,0 | 186 | 21,8 | 39,4 |

| KLSD-36 | 36 | 3 | 4,5 | 16,0 | 3,0 | 210 | 24,5 | 39,4 |

4 | 6,2 | 12,7 | 3,0 | 205 | ||||

| KLSD-40 | 40 | 4 | 6,2 | 13,8 | 3,0 | 220 | 27,2 | 59,7 |

| KLSD-44 | 44 | 4 | 6,2 | 15,0 | 3,0 | 234 | 30 | 65,0 |

| KLSD-48 | 48 | 4 | 6,2 | 16,0 | 3,0 | 249 | 32,6 | 70,5 |

Request for Information!

Would you like to speak to one of our advisers? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

For Businesses: Do you have questions about how RZPO can help your company? Send us an email and we’ll get in touch shortly, or phone +8(835)10001246977 between 09:00-23:00 +3 GMT Monday to Sunday — we would be delighted to speak (by phone English, Russian, Bulgarian languages).

Note: Your details are kept strictly confidential as per our Privacy Policy.